As an experienced garment accessories manufacturer, we know that we should not just follow the fashion steps while maintaining products quality, we must keep innovating to better serve our customers. Our ultimate goal is to reach a win-win situation: improve customer’s brand value and enhance our own value. In this post, I would introduce you what makes a hang tag.

Materials and Shapes

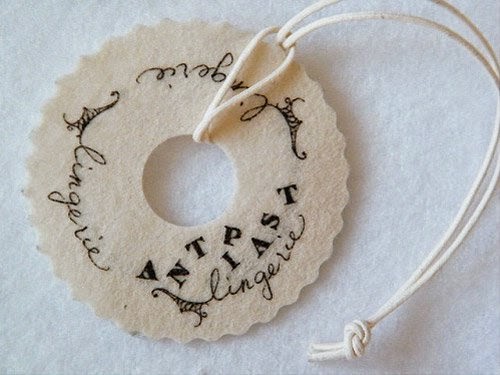

Most hang tags are made of paper materials. There are also hang tags that are made of plastics and metal. The shapes of hang tags are various. Most of the hang tags are rectangle shaped. There are also hang tags that are fold-shaped, circular , triangular...

Hang Tag Design

The design, printing and production of clothing hang tags all must be taken seriously. Especially the graphic design of the hang tag, designers must take it as a graphic advertising design. They must consider the following elements while designing: necessary ingredients instructions and washing guide. For functional clothing such as jackets, plastic body underwear and warm clothes, detailed instructions must be attached to the clothing hang tags.

Processing Technology

Apart from basic printing, many other different processing technologies are used in the process of hang tags. The combining application of various processing technologies can perfectly show the different styles of different brands. Read on to get to know the several commonly used processing technologies.

Lamination: lamination is a kind of surface processing technology after the printing process. Typically, the are two kinds of lamination materials: matte lamination and glossy lamination. The lamination materials can protect the paper materials, extend service life and protect the prints on the paper.

UV: UV printing is a kind of printing technology that use UV to dry and solidify ink. The UV printing technology can not only be used on paper and cardboard, it’s also widely used on many other low absorption or non-absorbent printing materials like plastic, foil, metal and heat sensitive materials. UV printing adds high gloss effect to the prints. Meanwhile, the UV printing can also prevent the prints from scratching damage. This technology is widely used on packaging and front cover of publications.

Gold Foil Plating: apply heated metal plate to printed materials to get golden text or images. Gold foiled prints are usually very clear, beautiful and vibrant. This technology is often used to highlight the design theme while printing trademarks, registered name.

Emboss/Deboss: use machine pressure to make the text or prints to get convex and concave effect, giving stronger visual and tactile impact to people.

Mount: stick together thin coated paper, specialty paper or offset paper after applying glue. The thickness of hang tags increased after mounted. Mount technology can make Hang tags look more high-end, satisfying customer’s special needs for thickness.

Though hang tags are small, they are the bridges that link clothing and consumer. They are inevitable products of modern fashion culture and play a active role in protecting the reputation of garment enterprises and promoting their products. Sinicline will continue developing more fashion and practical hang tags to show and improve your brand value!